Engineers from MIT and the National Renewable Energy Laboratory have designed a new heat engine, a thermophotovoltaic cell with no moving parts. The device can generate electricity from a heat source of 1900 to 2400°C. The team reports an unprecedented efficiency, more than 40%, a performance that is superior to that of traditional steam turbines (with maximum efficiency usually around 35%). This technology could pave the way to a completely carbon-free electricity grid.

Thermophotovoltaic cells (TPV) are photovoltaic cells optimized to convert infrared electromagnetic radiation into electricity (photovoltaic cells operate in the visible and ultraviolet light). This technology thus makes it possible to increase the range of wavelengths that can be converted into electricity.

In theory, the efficiency of a TPV cell can exceed 50%, but in practice, scientists have never exceeded 32% so far. The newly developed cell proves to be more cost effective than the steam turbines used today for power generation, as it can utilize higher temperature heat sources.

The machines on which the turbines rest depend on moving parts whose temperature is limited; heat sources above 2000°C would be much too hot and cause the materials to degrade. That is why scientists have been looking for alternatives to increase yields. † One of the advantages of solid-state power converters is that they can operate at higher temperatures with lower maintenance costs because they have no moving parts. † explains Asegun Henrya researcher in the Department of Mechanical Engineering at MIT and co-author of the paper presenting the device.

Multiple layers of material for maximum performance

Like photovoltaic cells, TPV cells can be made of narrow bandgap semiconductor materials – the bandgap is the energy separating the valence band from the conduction band or in other words, the energy to be obtained by the electrons to reach the conduction band (and conduct electricity). If a high-energy photon is absorbed by the material, it can electron through the band gap.

But so far, TPV cells have only shown relatively low yields, averaging around 20% (the record is 32%). Most existing TPV cells are based on low bandgap materials, which convert photons at low temperature and low energy (i.e. lower efficiency). To improve their efficiency, the researchers therefore looked for a way to capture higher-energy photons from a heat source with a higher temperature.

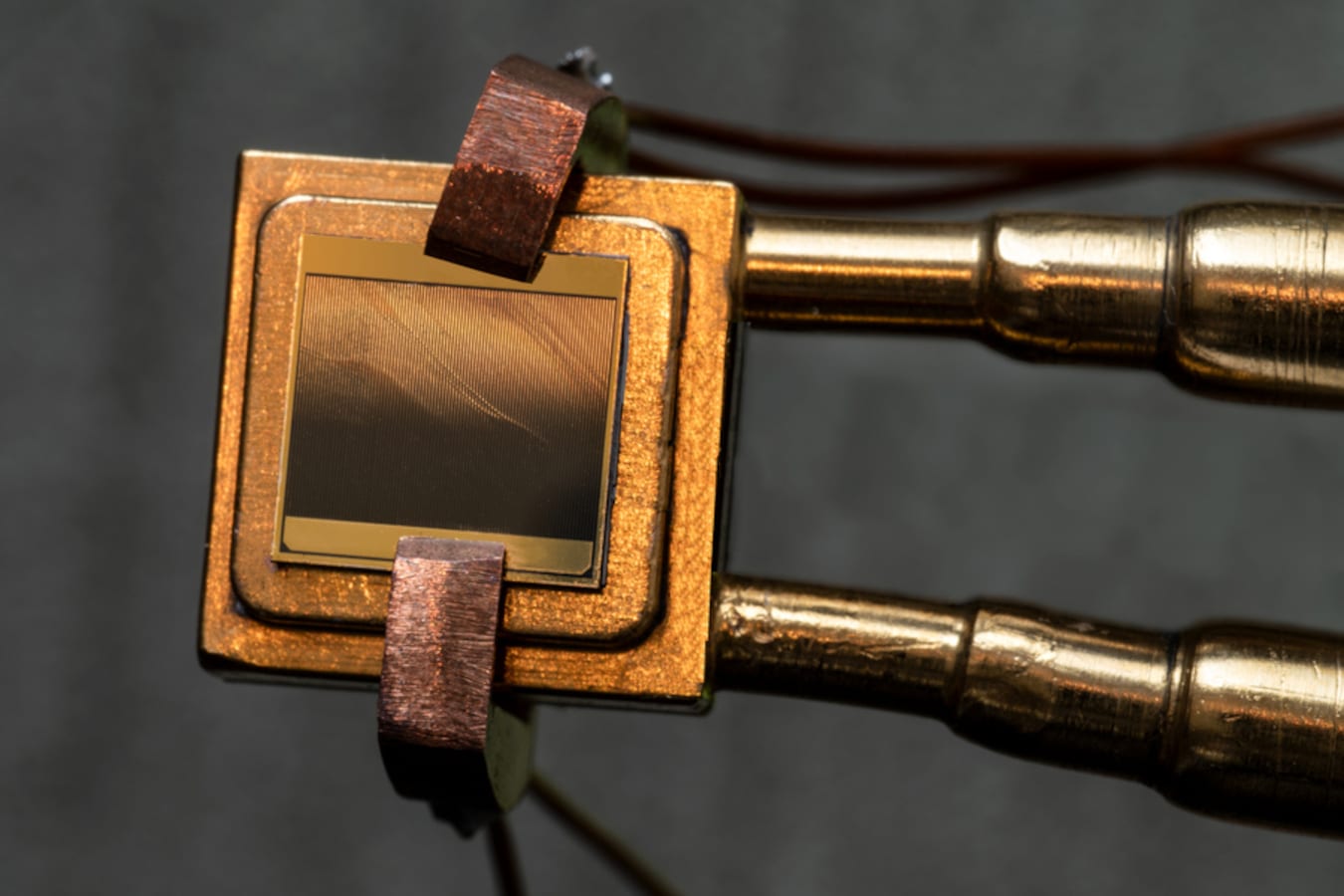

To do this, they used materials with higher band gaps (between 1.0 and 1.4 eV) and multi-junctions (multiple layers of material). The cell thus consists of a stack of three materials: on the surface is a high bandgap alloy, which rests on a slightly lower bandgap alloy, under which lies a mirror-like layer of gold.

peut être convertie en électricité (Pout), renvoyée vers l’émetteur (Pref) ou thermalisée en raison des inefficacités de la cellule et du réflecteur arrière (Qc). © A. LaPotin et al.</p>

<p>” data-medium-file=”https://trustmyscience.com/wp-content/uploads/2022/04/schema-cellule-thermophotovoltaique-300×280.jpg” data-large-file=”https://trustmyscience.com/wp-content/uploads/2022/04/schema-cellule-thermophotovoltaique.jpg” src=”https://trustmyscience.com/wp-content/uploads/2022/04/schema-cellule-thermophotovoltaique.jpg” alt=”thermophotovoltaic cell diagram” width=”505″ height=”471″ srcset=”https://trustmyscience.com/wp-content/uploads/2022/04/schema-cellule-thermophotovoltaique.jpg 505w, https://trustmyscience.com/wp-content/uploads/2022/04/schema-cellule-thermophotovoltaique-300×280.jpg 300w, https://trustmyscience.com/wp-content/uploads/2022/04/schema-cellule-thermophotovoltaique-500×466.jpg 500w, https://trustmyscience.com/wp-content/uploads/2022/04/schema-cellule-thermophotovoltaique-472×440.jpg 472w, https://trustmyscience.com/wp-content/uploads/2022/04/schema-cellule-thermophotovoltaique-390×364.jpg 390w” sizes=”(max-width: 505px) 100vw, 505px”/>

</picture>

</noscript><figcaption id=) The incident energy on the TPVs (Pincl) can be converted into electricity (Pfrom), returned to the sender (Pref) or thermally due to inefficiencies in the cell and rear reflector (Qc). © A. LaPotin et al.

The incident energy on the TPVs (Pincl) can be converted into electricity (Pfrom), returned to the sender (Pref) or thermally due to inefficiencies in the cell and rear reflector (Qc). © A. LaPotin et al.The first layer captures high-energy photons from a heat source and converts them into electricity; the lower energy photons passing through the first layer are captured by the second and converted in turn. Finally, photons passing through this second layer are reflected back to the heat source by the mirror, rather than being absorbed as waste heat – unused radiation is returned to the emitter.

Towards a completely carbon-free electricity grid

The team tested the cell by exposing it to a high-temperature lamp, which varied in intensity. Using a heat flux sensor, they examined how the cell’s energy efficiency – the ratio between the amount of energy produced and the amount of heat absorbed – varied with lamp temperature. † A 1.4/1.2 eV device achieved a peak efficiency of 41.1 ± 1% for a power density of 2.39 W/cm2 and an emitter temperature of 2400°C. A 1.2/1.0 eV device achieved a peak efficiency of 39.3 ± 1% for a power density of 1.8 W/cm2 and an emitter temperature of 2127°C “, reports the team in Nature†

et 1,4/1,2 eV (d) qui ont été fabriqués et caractérisés dans l’étude et leur irradiance spectrale associée, à la température moyenne de l’émetteur (un corps noir de 2150 °C). Un miroir en or situé à l’arrière de la cellule reflète environ 93% des photons situés sous la bande interdite, ce qui permet de recycler cette énergie. © A. LaPotin et al.</p>

<p>” data-medium-file=”https://trustmyscience.com/wp-content/uploads/2022/04/bandes-conversion-electricite-300×142.jpg” data-large-file=”https://trustmyscience.com/wp-content/uploads/2022/04/bandes-conversion-electricite.jpg” src=”https://trustmyscience.com/wp-content/uploads/2022/04/bandes-conversion-electricite.jpg” alt=”electricity conversion strips” width=”900″ height=”425″ srcset=”https://trustmyscience.com/wp-content/uploads/2022/04/bandes-conversion-electricite.jpg 900w, https://trustmyscience.com/wp-content/uploads/2022/04/bandes-conversion-electricite-300×142.jpg 300w, https://trustmyscience.com/wp-content/uploads/2022/04/bandes-conversion-electricite-500×236.jpg 500w, https://trustmyscience.com/wp-content/uploads/2022/04/bandes-conversion-electricite-472×223.jpg 472w, https://trustmyscience.com/wp-content/uploads/2022/04/bandes-conversion-electricite-390×184.jpg 390w” sizes=”(max-width: 900px) 100vw, 900px”/>

</picture>

</noscript><figcaption id=) The tandems of 1.2/1.0 eV (c) and 1.4/1.2 eV (d) fabricated and characterized in the study, and their spectral irradiance, associated with the mean emitter temperature (a black body of 2150 °C). A gold mirror on the back of the cell reflects about 93% of the photons below the bandgap, allowing this energy to be reused. © A. LaPotin et al.

The tandems of 1.2/1.0 eV (c) and 1.4/1.2 eV (d) fabricated and characterized in the study, and their spectral irradiance, associated with the mean emitter temperature (a black body of 2150 °C). A gold mirror on the back of the cell reflects about 93% of the photons below the bandgap, allowing this energy to be reused. © A. LaPotin et al.This TPV cell appears to be fully operational and efficient. † Thermophotovoltaic cells were the last important step in demonstrating that thermal batteries are a viable concept said Henry. The team plans to incorporate it into a grid-scale thermal battery: The system would absorb excess heat, store it (on a graphite backing), and convert it into electrical energy when sunlight conditions aren’t adequate.

It remains to design a device on a larger scale to consider a production system that can meet the needs. The cells used in these experiments measure approximately 1 cm²; for a grid-scale thermal battery system, they have to reach an area of about 900 m² and have to work in air-conditioned warehouses.

According to Henry, the infrastructure for the production of large-scale photovoltaic cells could be adapted to the production of TPVs. † The technology is safe, harmless to the environment during its life cycle and can have a significant impact on reducing carbon dioxide emissions from power generation ‘, he underlines. The proliferation of such network-scale thermal energy storage systems could eventually reduce global CO2 emissions by about 40% and charge electric vehicles (currently responsible for 15% of emissions) with CO2-free electricity.