It is sometimes confusedly thought that all materials have been discovered, that all combinations have been tested, that humanity has reached the end of its knowledge of materials. This is of course incorrect.

There is still tremendous progress to be made and NASA, in A press release taken back by Interesting Engineeringhas announced another giant step with an unprecedented alloy that describes it as 1000 times more resistant than its best current competitors.

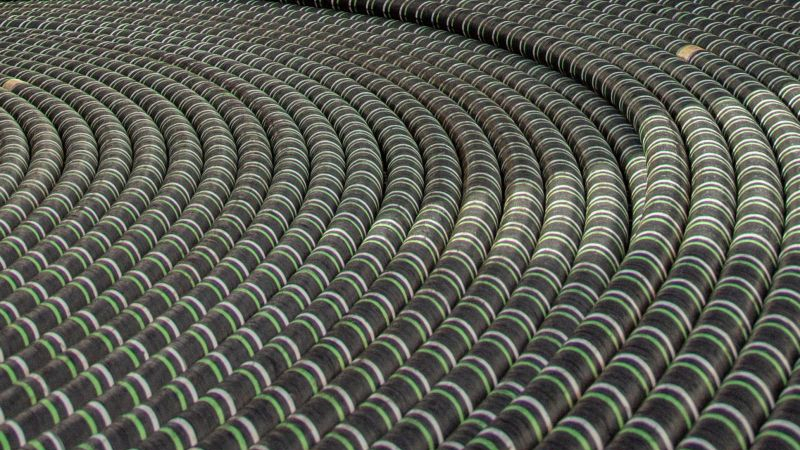

Called GRX-810, the thing designed to withstand the worst conditions of the worst missions is a so-called “oxide-dispersion reinforced” alloy (“Oxide dispersion-enhanced” or ODS, in English). Wikipedia describes this material as a matrix of metal (nickel, platinum, iron-aluminium…), into the interstices of which oxides are injected to enhance the capacities of the original material.

One of the great novelties lies in the method used: instead of good old successive tests for almost as many errors, the US agency found the formula of the GRX-810 thanks to the modeling of materials, so the preliminary computer simulation of their qualities and defects, combined with the additive techniques of 3D printing.

The time saved is immense: only thirty attempts would be enough to find the perfect formulation for this new, almost indestructible alloy. “What would have taken us years with a traditional trial and error process now takes weeks to lead to a discovery”explains Dale Hopkins, manager of NASA’s Transformational Tools and Technologies project.

Unbreakable (or almost)

The qualities of the GRX-810 are indeed remarkable: it can withstand temperatures of almost 1100 degrees Celsius and is 1000 times more durable in these extreme conditions. It’s also more malleable and three and a half times more flexible, allowing for more twisting and straining before finally breaking.

“This discovery is revolutionary for the development of materials, it is written in the release of the US space agency. New types of lighter, stronger materials are playing a vital role in transforming the future of spaceflight. Previously, an increase in tensile strength resulted in a decrease in the material’s ability to twist and deform before breaking, making our new alloy remarkable.”

As these modern research methods improve over the years, new discoveries are likely to find their way into labs around the world, taking the science of space travel, manned and unmanned, by leaps and bounds. The next Parker probe, called the craft that recently began to caress the sun’s inner coronacould thus be able to submerge its antennae even closer to the surface of our star.